Improved Servicing and Maintenance

Technologically Advanced

Overview

Digital design and manufacturing

The Next-Generation 737 is the first family of single-aisle jetliners designed concurrently using 100 percent 3D digital design and manufacturing technology. Concurrent design ensured that all Next-Generation 737 models enjoy maximum commonality and share the benefits of our ongoing technology and performance improvement program.

Greater operational flexibility

Today's most advanced navigation and situational awareness technologies give the Next-Generation 737 access to routes and approaches unavailable to less advanced aircraft. Improved takeoff and landing performance even at high elevations and on short runways provides operators greater flexibility.

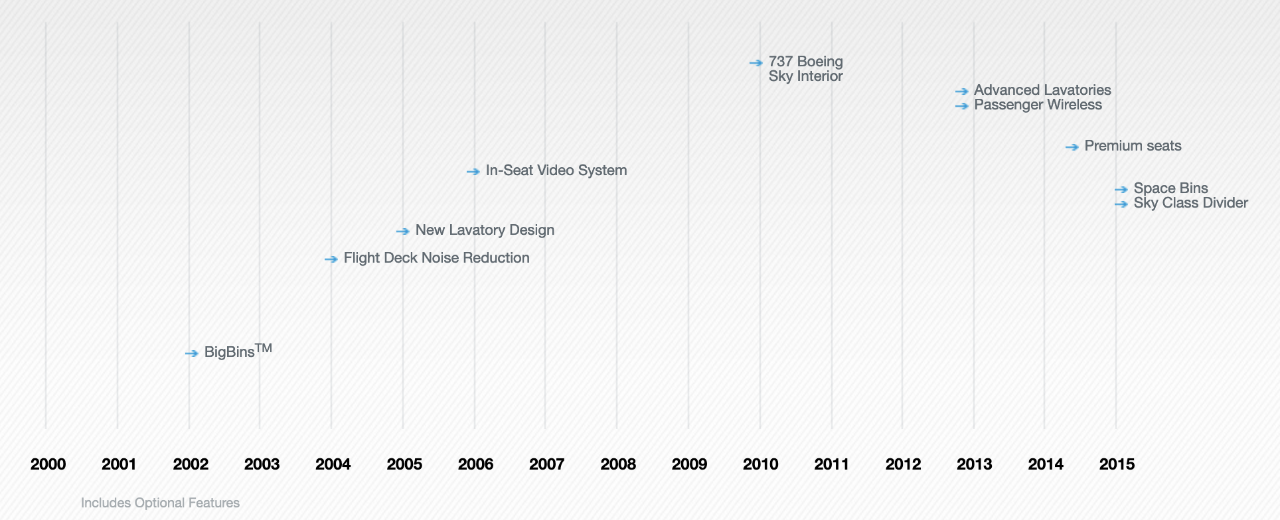

Enhanced passenger experience

Passengers appreciate more room for carry-on items in bigger overhead bins. Optional features such as the latest in-flight entertainment systems, allows airlines to deliver information, customized programming, and revenue-generating content to every seat.

Reduced maintenance and improved environmental performance

Engine technology improvements, blended winglets and carbon brakes are among the enhancements that reduce maintenance and improve the environmental performance of today's Next-Generation 737. With an eye to the future, Boeing is committed to sustaining the technology leadership of the 737 family.

Features

- Optional Blended Winglets

- Enhanced Landing Gear

- Advanced Wing Design

- MSG-3 Rev. 2 Maintenance Program

- Leading Flight Deck Technologies

- Efficient CFM Engines

- 100% Digital Design

- Inspired Interior Design

- Improved Lavatories

- Advanced Aircraft Assembly Process

- Advanced Materials

- Improved Corrosion Resistant Materials

- Improved Auxiliary Power Unit

Advanced Wing

More Advanced Wing Design

Longer range, improved takeoff and landing performance

The wing of today's Next-Generation 737 is a new design compared to the 737 Classic, with greater area for more lift and an advanced geometry to reduce drag. Simpler control surfaces reduce weight and maintenance requirements. The new wing has a larger volume, so it can hold more fuel for longer range. Because it improves takeoff and landing performance, the new Next-Generation 737 wing also helps reduce community noise.

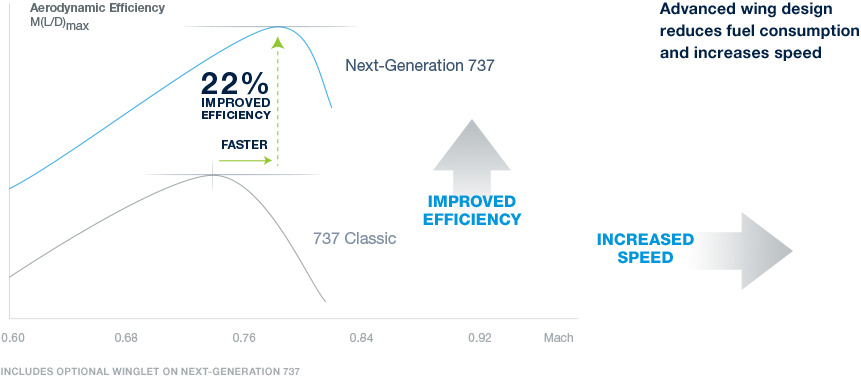

Next-Generation 737 Superior Design*

- 25% more wing area

- 30% greater fuel capacity

- 22% greater aerodynamic efficiency

* Next-Generation 737 versus 737 Classic

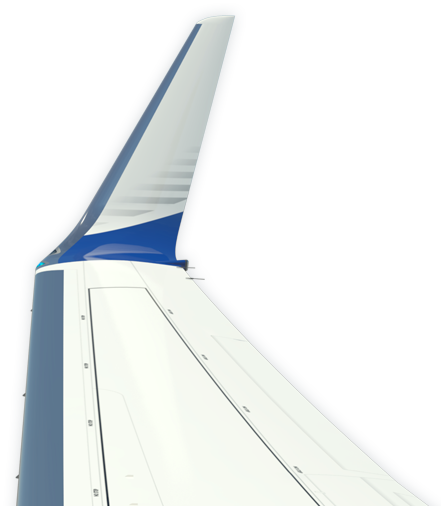

Innovative Winglet Technology

Innovative

- Increase range, payload, and takeoff performance

- Reduce fuel consumption and engine maintenance cost

- Reduce noise

- Increases residual value

Adding blended winglets to the highly efficient Next-Generation 737 wing boosts range, payload, takeoff and landing performance, and fuel economy. The improved performance allows pilots to use takeoff procedures that decrease wear and tear on engines and reduce community noise. The distinctive appearance of blended winglets can help differentiate the airline's brand. And as an additional benefit, winglets increase the airplane's residual value.

Superior Aerodynamic Design

Greater aerodynamic efficiency

The aerodynamic efficiency of the Next-Generation 737 wing increases the speed at which the airplane can cruise economically. Improved takeoff and landing performance translates into better performance at high-altitude airports and on short runways.

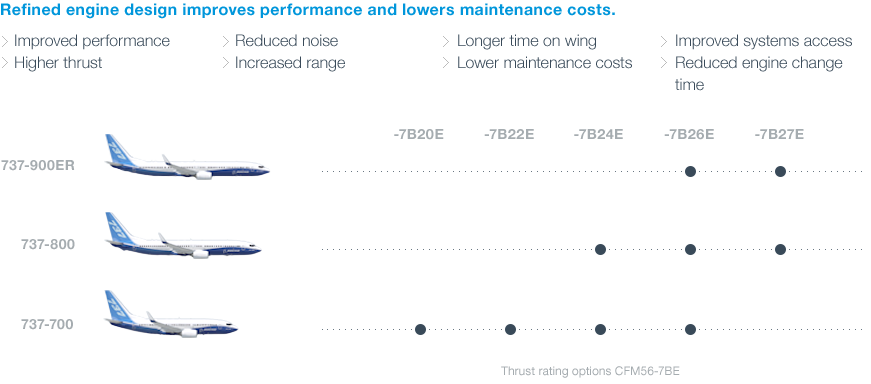

Advanced Engine

One Engine Multiple Thrust Options Offer Market Versatility

Increased asset value from commonality

Strategic partnerships, spare parts pooling and fleet expansion are easier for the 737, thanks to a high degree of commonality and standardization. Asset value and liquidity are enhanced because all three Next-Generation 737s share the same efficient CFM56-7BE engine. A range of available thrust ratings allows airlines to match engine performance to operational requirements for longer time on-wing.

CFM56-7BE Engine Improvements

CFM International (CFM) is using advanced computer programs and three-dimensional design techniques to improve airfoils in the high- and low-pressure turbines for enhanced engine performance. In addition, CFM is improving engine durability and reducing parts count to achieve lower maintenance costs. The CFM56-7BE engine enhancement program entered airline service in mid-2011 to coincide with Boeing Next-Generation 737 airframe improvements.

The CFM56-7BE-powered Next-Generation 737 enhanced airplane/engine combination provides a two-percent improvement in fuel consumption, which equates to a two-percent reduction in carbon emissions.

Engine performance improvements lower fuel consumption by approximately 1%.

- Improved high pressure turbine

- Optimized low pressure turbine

- Improved primary nozzle and plug

- Refined aft strut fairing heat shield

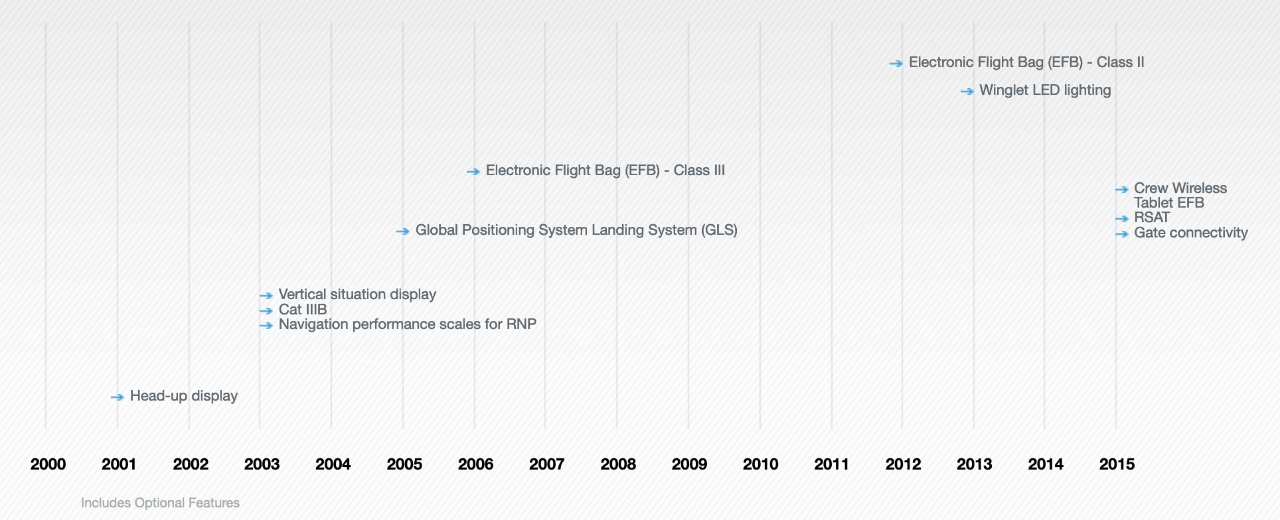

Advanced Flight Deck

Innovative Flight Deck Technologies

First to demonstrate flight deck technology advantages

The Next-Generation 737 is leading the way in the development and implementation of flight deck technologies that will enable the aviation industry to meet the strong demand for air transport. No airplane has gained as much operational experience using technologies such as head-up display (HUD), vertical situation display, Global Navigation Satellite System (GNSS) Landing System (GLS) and Required Navigation Performance (RNP). These systems enhance safety, and pilots can fly more stable and precise paths with little or no new ground infrastructure. Air traffic controllers can grant a suitably equipped Next-Generation 737 the most direct and economical routes and clearance to land and takeoff under weather conditions that would require other airplanes to divert or stay on the ground.

Familiar look and feel

All Boeing flight decks feature large-displacement flight controls. Controls are interlinked so that both pilots are immediately aware of any control input — whether from the other pilot or from the autopilot. Flight deck automation can smooth the flight and relieve the flight crew of many routine tasks, while keeping pilots aware of the airplane's situation. Pilots always have full authority to fly the airplane and to make crucial flight decisions.

These flight deck technologies are offered as optional features. This allows the customers to design their flight deck configuration to their specific requirements while minimizing weight and maintenance costs.

RNP Benefits

The first commercial airplane certified for RNP of 0.10 nautical miles

With Required Navigation Performance (RNP) certified at navigation precision of 0.10 nautical miles, the Next-Generation 737 qualifies for the most economical routes in busy airspace and the most direct approaches to runways restricted by noise regulations or terrain. Able to fly precise, preselected, 3D RNP flight paths without ground-based navigational aids, the Next-Generation 737 can maintain punctual schedules while other airplanes follow less efficient flight paths, circle in holding patterns, divert to other airports or stay on the ground. RNP capability delivers immediate operational advantages and supports evolving efforts to minimize flight delays and improve airspace utilization.

The Next-Generation 737 is the first airplane in its class certified to meet 0.10 nmi RNP.

Accommodates Challenging Approaches

- Reduces track miles

- More efficient operations into airports restricted by terrain and airspace

Enables Inclement Weather Operations

- Reduces landing minima

- Decreases cancellation and diversion rates

Saves Track Miles

- Providing more direct routing

- Saving time and fuel

- Fuel savings can be significant for high frequency operations

0.10 nmi RNP capability requires optional equipment

Advanced Structure

- Better Structural Efficiency

- High Quality Assembly

- Improved Servicing & Maintenance

Better Structural Efficiency

Next-Generation 737 is the first single-aisle jetliner designed concurrently as a family using 100% 3D digital design and manufacturing technology.

Higher Quality Assembly

Passenger Experience

The spacious, comfortable look and feel of the 737 Boeing Sky Interior is further enhanced by soft LED lighting, thoughtfully balanced for leisure, work or rest. The lighting can gently simulate a full flying day for longer flights, gradually changing through a spectrum of lighting from day into night. Because LED lights have no filament, they last 10 to 20 times longer than incandescent lights that are used on airplanes today. The LED lighting also generates less heat than conventional cabin lighting.

- Prelanding

- Meal Service

- Relaxation

- Cruise

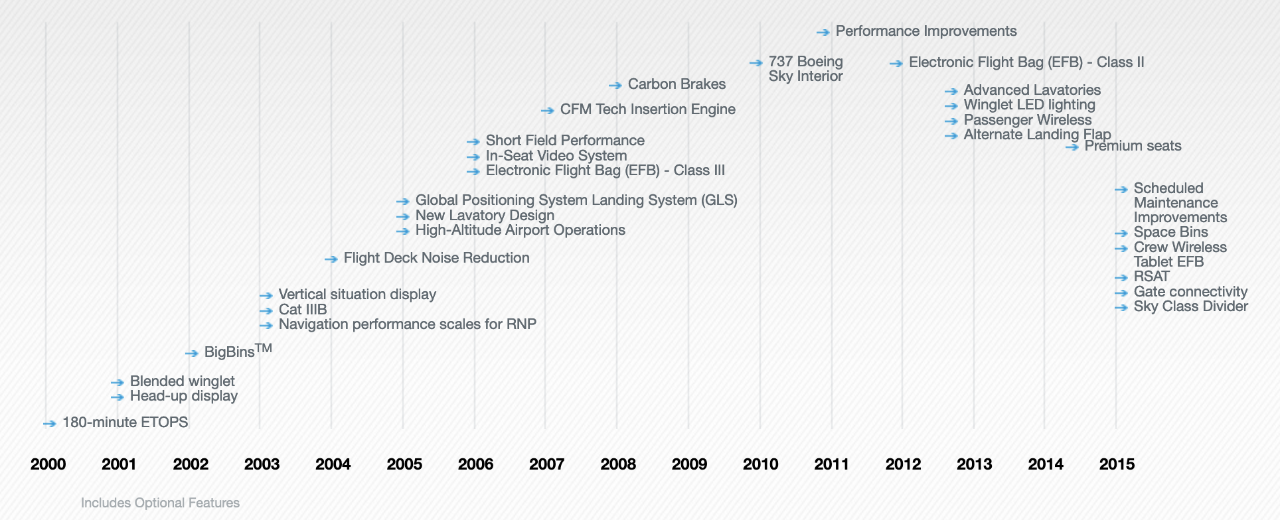

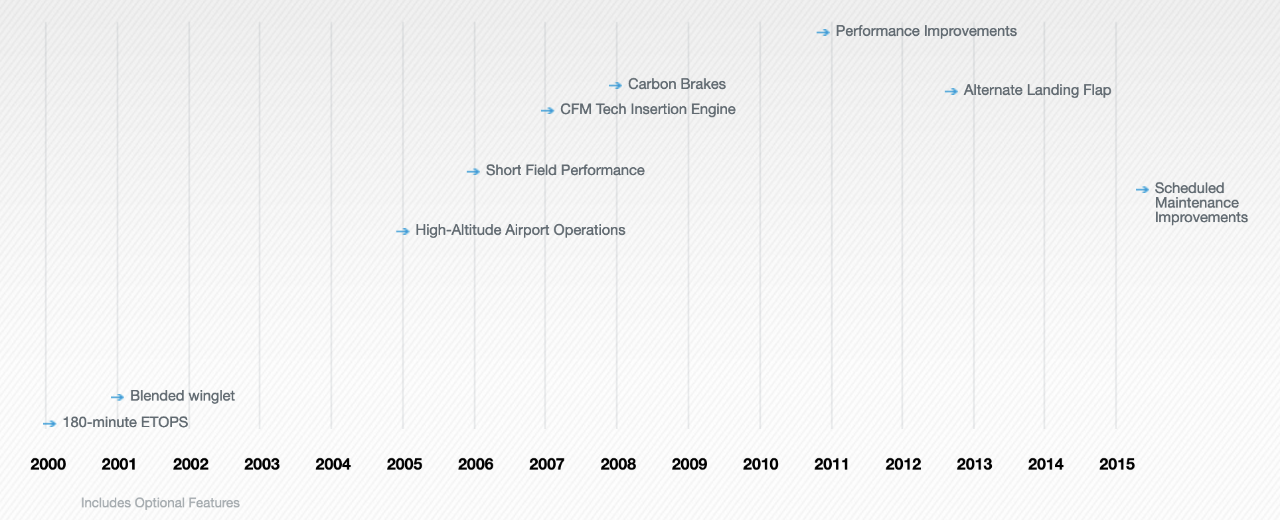

Continuous Innovation

- All

- Improved Performance

- Improved Comfort

- Improved Navigation

Proven Performance

Performance

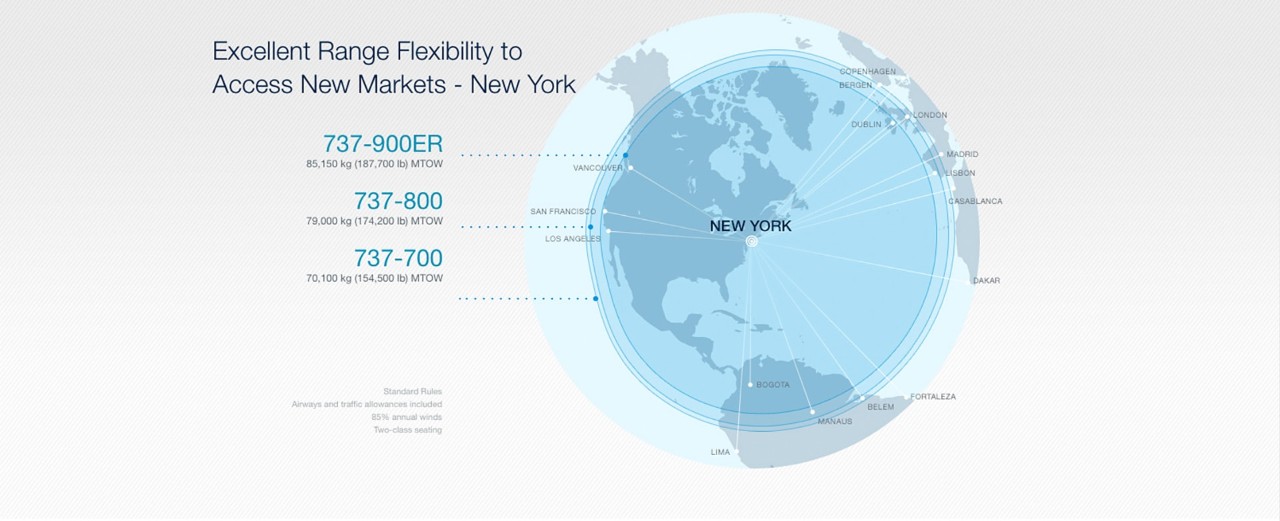

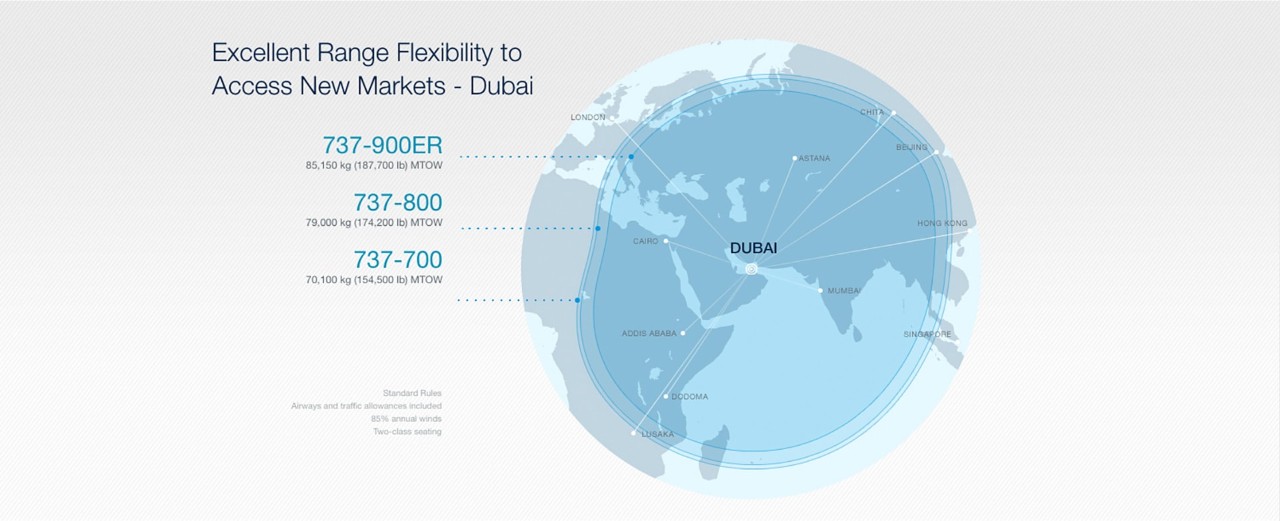

More range with more Payload

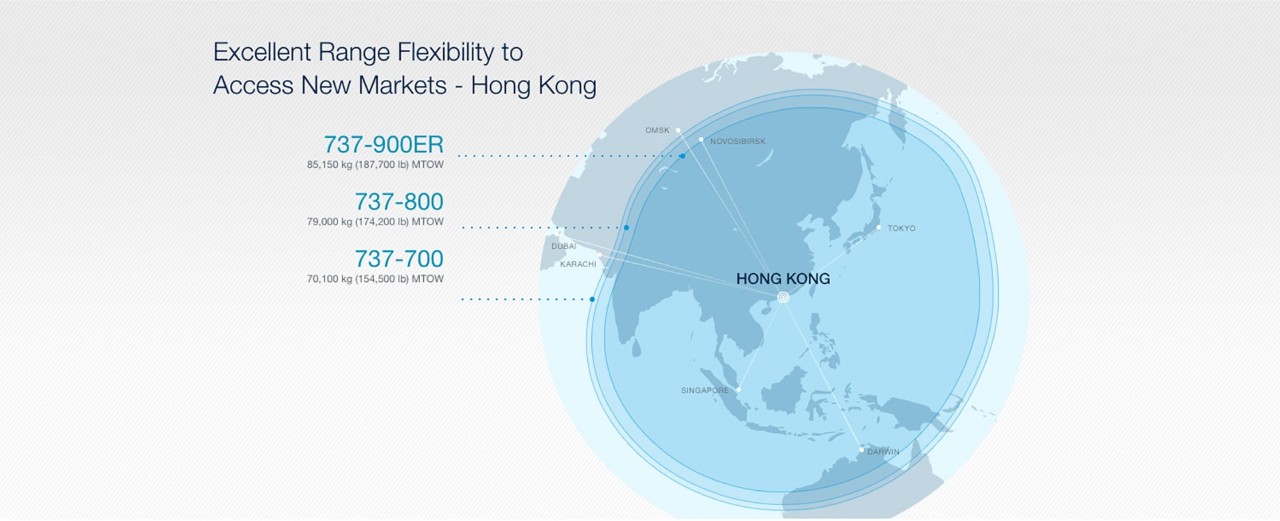

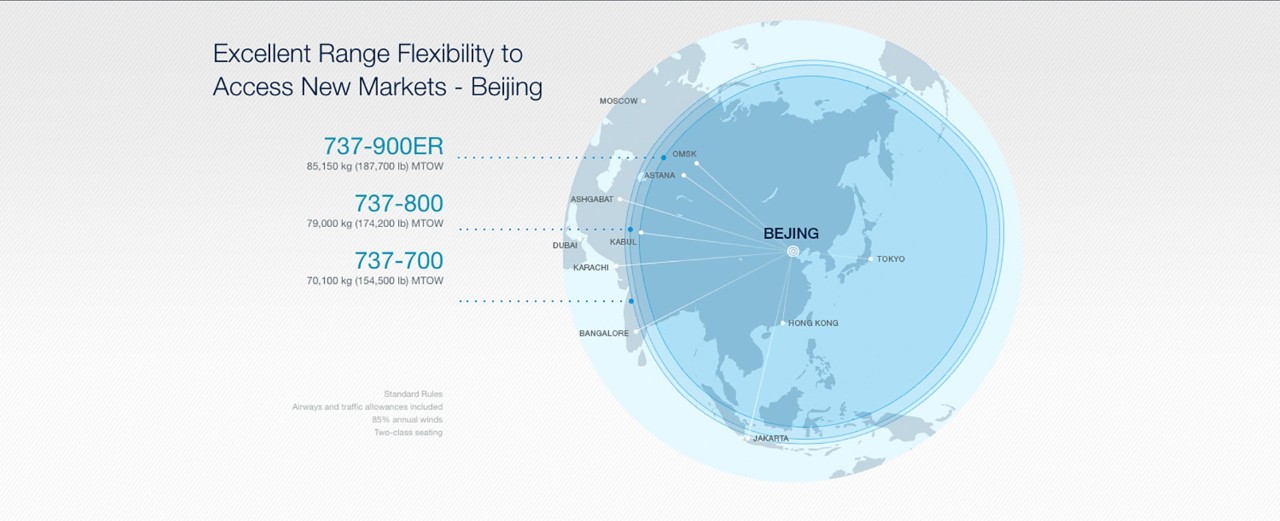

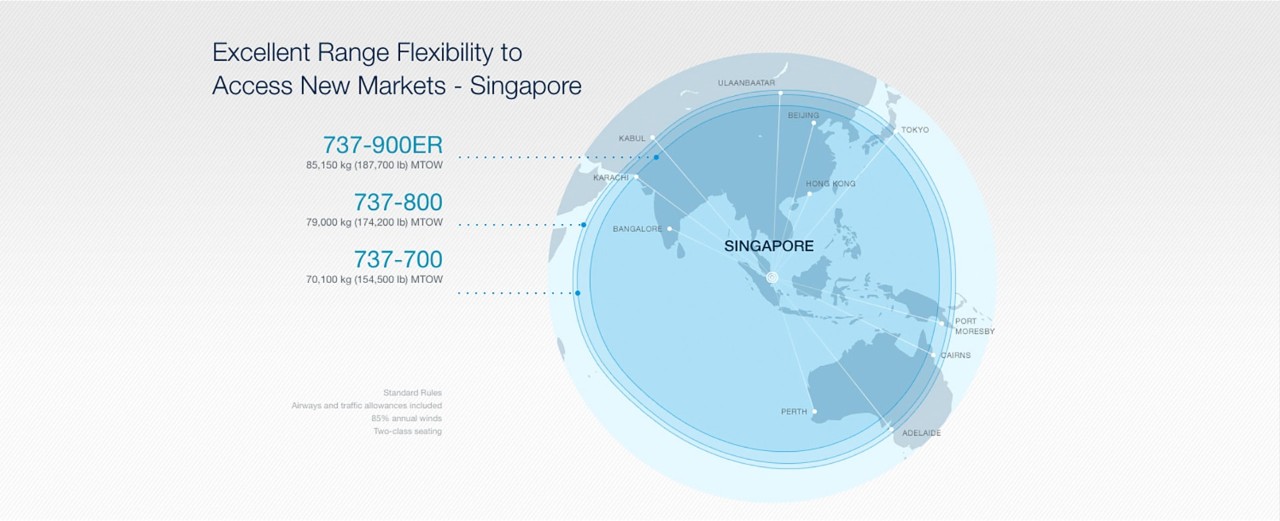

Superior range enables the Next-Generation 737 to serve more markets, with a full revenue payload. All three 737 models can fly transcontinental distances and all can be equipped and certified for ETOPS flights. The ability to assign any of the three airplane sizes to a route — virtually without concern about range limitations — gives airlines unparalleled ability to match capacity to actual demand and to respond to near- and long-term demand fluctuations.

- London

- New York

- Dubai

- Hong Kong

- Beijing

- Singapore

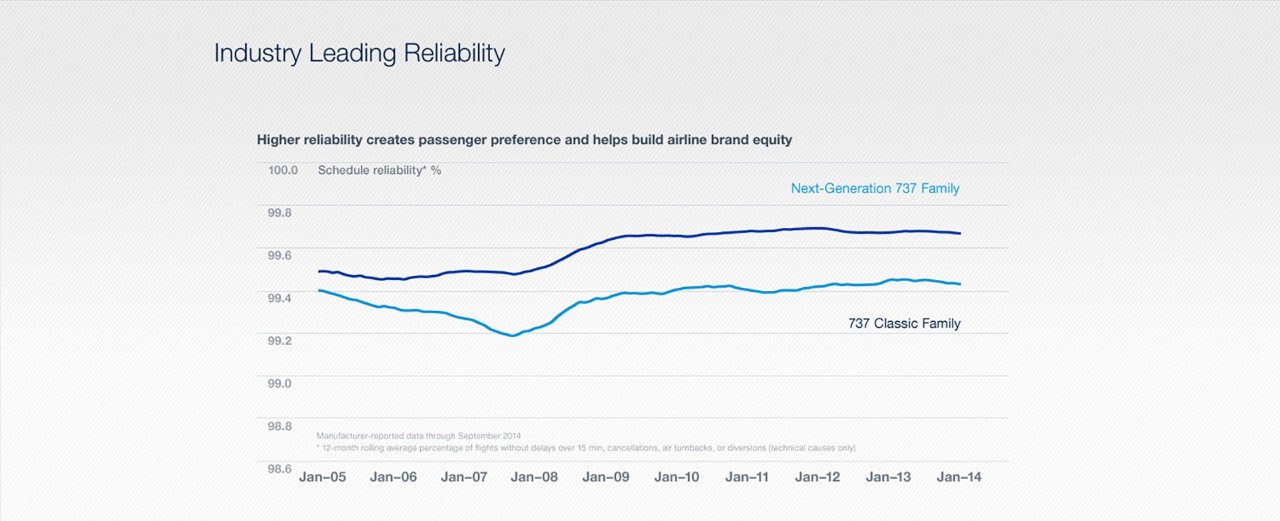

- Leading Reliability

Profitability

Next-Generation 737 is More Efficient

The Next-Generation 737 was developed by listening to our 737 customers to understand where we could improve all aspects of 737 operations. That collaboration allowed us to identify the right new technologies to greatly reduce maintenance costs. Travelers benefit directly from the dramatically lower maintenance requirements, as passengers on Next-Generation 737s are less likely to experience schedule delays due to mechanical issues.

Next-Generation 737 is designed for maintainability

- Next-Generation 737 was designed with the latest technology and is the industry leader in reliability.

- More than 20 airlines participated in defining design solutions to meet operational maintenance needs.

- The maintenance program was designed under MSG-3 Rev 2 requirements to optimize maintenance tasks.

- Maintainability by design approach utilizes 100% digital design to verify access and removability.

- Fuel efficient engines stay on-wing longer than any other single aisle airplane engine in commercial aviation.

- The Next-Generation 737 design offers a flexible maintenance program with longer check intervals and more revenue flying days.

Commonality

With three sizes, the Next-Generation 737 family offers airlines unequaled opportunity to optimize capacity and performance to actual demand and range requirements, while maintaining the powerful economic advantages of a single-type fleet.

One airplane in three sizes

As new market opportunities develop, Next-Generation 737 operators can grow their fleets with a lower investment in parts, equipment, and training:

- Common flight deck

- Common engines

- Common airframe spares

- Common ground handling equipment

Environmentally Progressive

Quieter for the Community

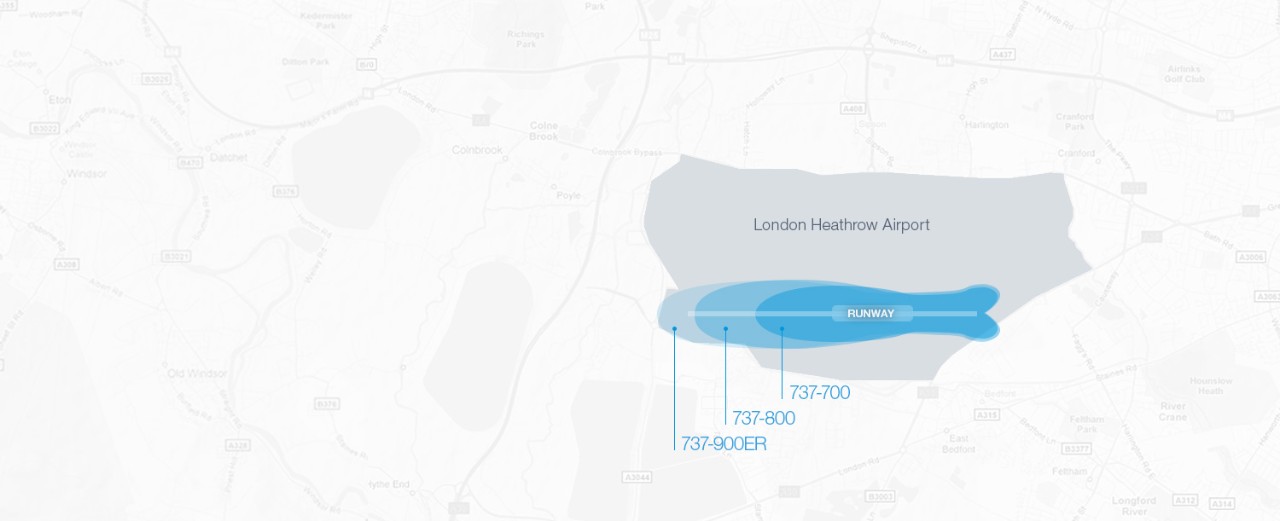

Next-Generation 737 Family Noise Contours

Decreasing the noise of airplane arrivals and departures is an important measure of environmental performance, especially to communities near airports. The Next-Generation 737 is quiet enough on takeoff and landing to give operators maximum flexibility to schedule flights into and out of restrictive airports, including London's stringently regulated Heathrow Airport.

Noise stays within the boundary of the airport

At most airports, 737 85-dBA noise levels stay within the airport boundary. This is the approximate noise of a truck driving along a highway. Because community noise impact is low, the 737 enjoys access to highly regulated airports, even during restricted hours of operation.

Maximum thrust engines with cutback

NADP 1 (ICAO-A)

85-dBA Takeoff noise contours

500-nmi mission, Full passenger payload

737-700/-800/-900ER with optional winglets

Cleaner for the Community

Environmentally Progressive Cleaner, Quieter and More Efficient Operations

People want to feel that they can be environmentally responsible when they fly, whether it is to visit with family and friends, to conduct business or to explore new places. With improved fuel efficiency for significantly lower CO2 emissions, the Next-Generation 737 already meets future emissions standards and surpasses current standards for noise and NOx emissions. Boeing continues to apply technology advances to make the Next-Generation 747 even cleaner, quieter and more fuel-efficient. Because when it comes to the environment, less is more.

Clean flying and a clean conscience

Airlines and passengers can rest assured that the Next-Generation 737 is well ahead of today's environmental standards. Beyond the economic benefits of thrifty fuel consumption, the Next-Generation 737 uses resources sparingly and produces less carbon dioxide per seat than other airplanes in its class.

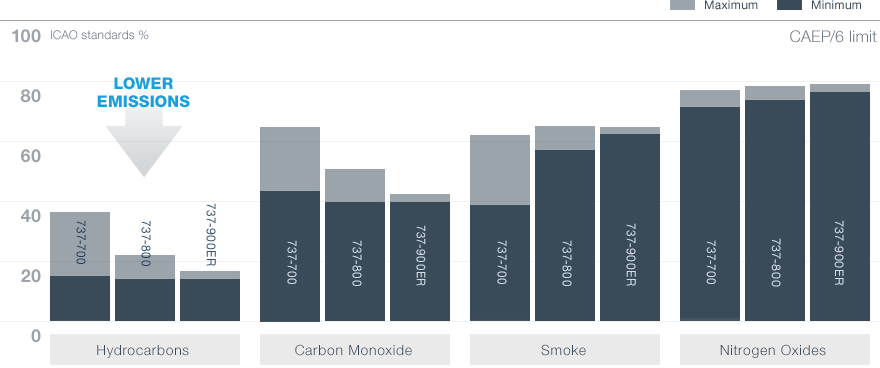

Clean by all emission metrics

Structural efficiency, an advanced wing and the latest engine technology help the Next-Generation 737 achieve excellent fuel economy and low emissions in all emission categories. All Next-Generation 737 family members beat NOx emission targets established by the International Civil Aviation Organization (ICAO) Committee on Aviation Environmental Protection (CAEP)/6 by a margin of at least 20 percent.

More Efficient Operations

Environmentally Progressive Cleaner, Quieter and More Efficient Operations

- 9%-14% reduction in carbon emissions and fuel consumption per seat

- 20% below CAEP/6 limits for NOx

- Quieter than Stage 4 noise standard

- Advanced structural design

- Advanced wing design

- Advanced engine design

Our Environmental Plans and Commitments

100%

ISO 4001

75%

of research

25%

better

15%

improvement

ISO 14001 certification planned for all manufacturing sites.

Our environmental commitment spans the entire life cycle of our jetliners—from the offices where airplanes are designed, through the manufacturing process, to the operation and maintenance of the airplane in commercial service, and ultimately to the recycling of resources from retired aircraft. As a recognized Lean+ innovator, Boeing Commercial Airplanes has or will achieve certification for all manufacturing sites under stringent ISO environmental management standards.

Characteristics

- 737-700

- 737-800

- 737-900ER

737-700

| Passengers 2-Class Configuration | 141 |

| Passengers Maximum Seating | 149 |

| Length | 33.6m (110 ft 4 in) |

| Wingspan | 35.8 m (117 ft 5 in) |

| Height | 12.5 m (41 ft 3 in) |

737-800

| Passengers 2-Class Configuration | 178 |

| Passengers Maximum Seating | 189 |

| Length | 39.5m (129 ft 6 in) |

| Wingspan | 35.8 m (117 ft 5 in) |

| Height | 12.5 m (41 ft 3 in) |

737-900ER

| Passengers 2-Class Configuration | 193 |

| Passengers Maximum Seating | 220 |

| Length | 42.1 m (138 ft 2 in) |

| Wingspan | 35.8 m (117 ft 5 in) |

| Height | 12.5 m (41 ft 3 in) |