Dedicated expertise and infrastructure

When you need the unquestioned results that only come from the most highly qualified testing facilities with a highly skilled and knowledgeable staff, you can be confident that Boeing will deliver the electromagnetics testing results you want.

Large or small, aerospace, automotive, industrial or military, Boeing’s testing facilities can support almost any electromagnetic testing that you have. The demands of electromagnetic effects confront Boeing daily in its commercial and military markets. Capitalize on that dedicated expertise and infrastructure.

Bring your electromagnetics testing requirements to Boeing. Be confident that Boeing works for you.

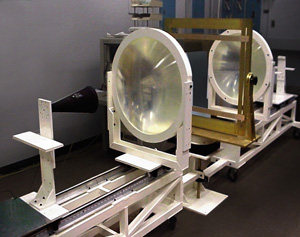

Antenna and radar cross-section testing

Boeing antenna and radar cross-section (RCS) testing ranges consist of indoor and outdoor facilities suitable for measuring nearly any test article at a variety of locations across the United States. Many of these test ranges can collect antenna pattern and RCS data on the same test articles. Boeing test engineers are highly skilled, and the test facilities are highly configurable, allowing unique and hard-to-find test capabilities to be provided.

Small compact ranges for RCS and antenna patterns

- Test articles up to 10 feet in length

- 500 MHz to 50 GHz

Very large compact range for RCS and antenna patterns

- Test articles up to 50 feet in length

- 120 MHz to 40 GHz

Near-field RCS range

- Test articles up to 70 feet in length

- 2 to 18 GHz

Small and large near-field antenna scanners

- Test articles up to 50 feet in length

- 4 to 100 GHz

Outdoor antenna ranges

- Test articles up to 70 feet in length

- 30 MHz to 50 GHz

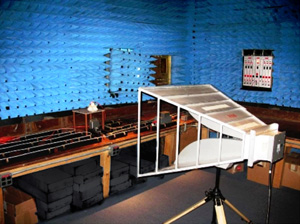

Electromagnetic interference and compatibility

Boeing offers a wide range of electromagnetic interference and compatibility (EMI/EMC) testing of electronic devices, components, subsystems and systems in dedicated, certified shield rooms and anechoic chambers. Highly skilled test teams also perform aircraft certification testing (such as safety of flight) on operational production and experimental aircraft and can be deployed around the world.

EMI/EMC chambers

- Certified shield rooms of various sizes

- Anechoic and mode-stirred chambers

- Operations with MIL-STD-461, MIL-STD-462 and RTCA DO-160 standards

- National Voluntary Laboratory Accreditation Program–certified laboratory

Aircraft system testing

- Safety-of-flight certification

- High-intensity radiated field

- Production and experimental aircraft

- Worldwide deployment

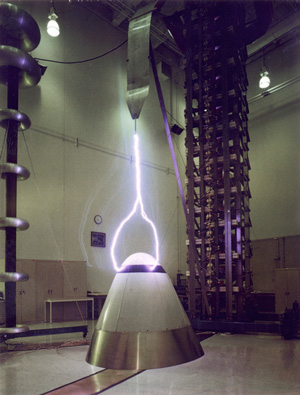

Direct and indirect lightning effects

Boeing offers testing of direct and indirect lightning effects using high-voltage and high-current waveforms. The highly skilled electromagnetic effects test engineers can often develop innovative test methods for prototype or difficult-to-handle test parts.

Direct effects testing

- Composite structures, surfaces and installations

- Composite bonding and grounding

- Lightning protection systems

- Fastened and bonded joint testing

- High-voltage arc attachment (2 megavolt peak)

- Airplane system safety verification

- Precipitation static testing

- RTCA DO-160, Section 23

- Consistent with MIL-STD-461

- Wide variety of waveforms

Indirect effects testing

- Certified shield rooms

Radio frequency and infrared material properties

Boeing materials measurement laboratories offer destructive and nondestructive radio frequency (RF) and infrared (IR) testing of material electrical properties. In addition to typical material testing (such as permittivity, permeability, reflectance and transmittance), the highly skilled staff routinely develops innovative testing methods and fixtures for hard-to-test materials such as liquids and adhesives.

RF material testing

- Waveguide bands: 410 MHz to 18 GHz

- Coaxial: 45 MHz to 18 GHz

- Free space: 2 to 110 GHz

- Pressed waveguide: 2.6 to 18 GHz

- Resonant cavities: 1.1 and 8 to 26 GHz

- Bistatic (arc) fixtures

- X/Y scanner for large samples

- High temperature

- In-service field testing

- Custom test equipment development and design

IR material testing

- Reflectance

- Diffuse, specular, total from ambient to elevated temperatures

- Ultraviolet (UV), visible (Vis), near IR (NIR), IR

- Grazing angle at laser lines

- Transmission

- Specular, total hemispheric

- UV, Vis, NIR, IR

- Scatter bidirectional reflectance distribution function (BRDF)

- 360-degree, reflection, transmission

- Selected lines, Vis, NIR, IR

- Haze

- Gloss

Request more information from Boeing Testing Services

The following information will be provided to our support staff who will contact you to identify the Boeing services and facility that will meet your needs.

Contact Boeing Testing Services via email at bts@boeing.com.

Current Boeing airplane customers: Are you a current owner or operator of a Boeing-delivered airplane seeking maintenance, repair or overhaul services; maintenance documents; engineering drawings; spare parts; or resolution of in-service issues? See MyBoeingFleet.com for direct, personalized access to information essential to the operation of Boeing-delivered aircraft.