Prove your products in our environments

Product developers from a wide variety of fields have come to trust Boeing for environmental testing of their products in harsh and potentially damaging environments. Boeing lab test facilities and teams have played a crucial role in ensuring that new and experimental products — from commercial and military aircraft, to automobiles, to satellites, to spacecraft — are equal to the challenges of the harsh conditions in which they operate, including extreme cold and heat, vacuum and pressure, solar radiation, rain, humidity, vibration, acoustic noise, and shock.

From the earth to the skies and beyond, prove your products in Boeing environments first.

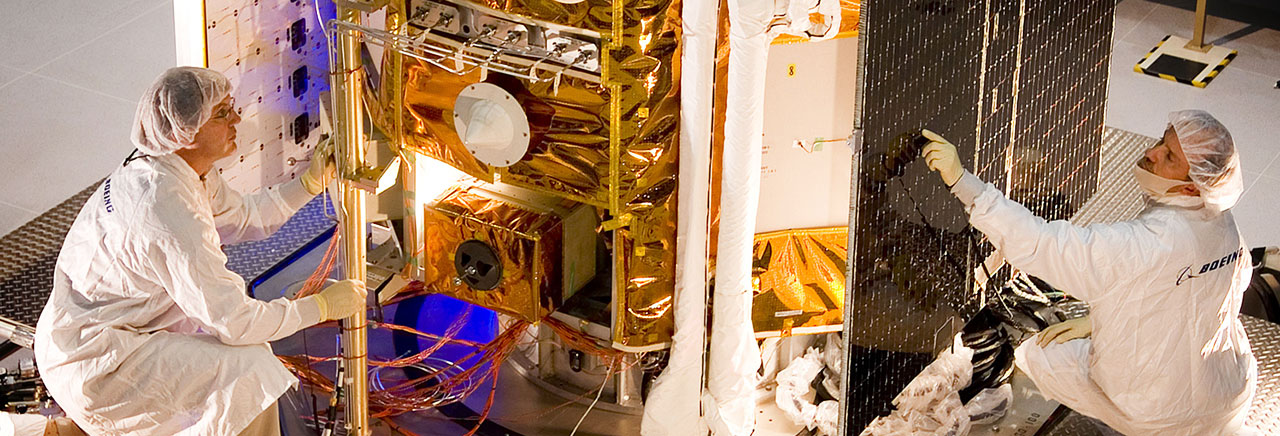

Space environmental testing

Boeing’s Space Environmental Test Facility in El Segundo, California, features a variety of capabilities specifically designed to test products against the harsh conditions of space. With decades of experience building and testing satellites, our labs can be used to simulate dynamic launch and space environmental conditions, including extreme cold, solar and electromagnetic radiation, vibration, and vacuum. Some key test capabilities are highlighted below.

- Our large (68,000 cubic-feet/20,726.4 cubic meters) acoustic test chamber can accommodate very large test articles and is able to test against vibration within a realistic gaseous simulated atmosphere. The lab is equipped with two 20-hertz and two 50-hertz WAS 3000 horns and four 200-hertz EPT 200 horns and is completely insulated and isolated from external interferences. The chamber performs at an overall sound pressure level (OASPL) of 155 decibels.

- Our 45-by-35-by-40-foot (13.7-by-10.7-by-12.2-meter) thermal vacuum chamber is able to simulate the extreme environment of space in both vacuum and cold with a shroud temperature liquid nitrogen capability of minus 320 degrees Fahrenheit (minus 195 degress Celsius) and a gaseous nitrogen range from minus 250 F (minus 157 C) to 250 F (121 C). It can be configured to simulate ambient solar radiation and is large enough to accommodate a variety of test article dimensions, even multiple test articles at once.

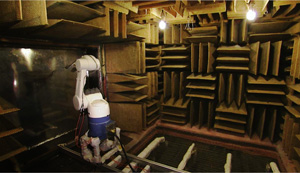

- Our large anechoic chamber (31.6 by 39.3 feet/9.6 by 12 meters and 26.5 feet/8 meters high) provides the ability to conduct antenna radiation patterns, electronic magnetic interference and compatibility (EMI/EMC), and payload testing via air linking the radio frequency (RF) signal to and from a satellite. The chamber is highly flexible accommodating various types of power supply sources with multiple power connections.

Noise test services

The Boeing Noise Engineering Laboratory has an expert staff and state-of-the-art equipment ready to help you isolate and measure noise and its effects. Our dedicated noise facilities and sophisticated information-handling systems make our laboratory one of the best in the world.

The Interior Noise Test Facility features an anechoic and a reverberant chamber, and it tests and measures noise from environmental control systems and hydraulic systems.

The Materials Test Center accommodates structural acoustics testing on a variety of components and assemblies. It houses a flow bench and impedance tubes to test acoustical resistance and impedance and Rayls.

The Quiet Air Facility is a versatile, general-purpose hemianechoic chamber with two muffled air supplies and controls for developing and testing the design of environmental control systems and components, calibrating instruments, and developing and verifying small- to medium-size mechanical and electrical components and systems.

Request more information from Boeing Testing Services

The following information will be provided to our support staff who will contact you to identify the Boeing services and facility that will meet your needs.

Contact Boeing Testing Services via email at bts@boeing.com.

Current Boeing airplane customers: Are you a current owner or operator of a Boeing-delivered airplane seeking maintenance, repair or overhaul services; maintenance documents; engineering drawings; spare parts; or resolution of in-service issues? See MyBoeingFleet.com for direct, personalized access to information essential to the operation of Boeing-delivered aircraft.