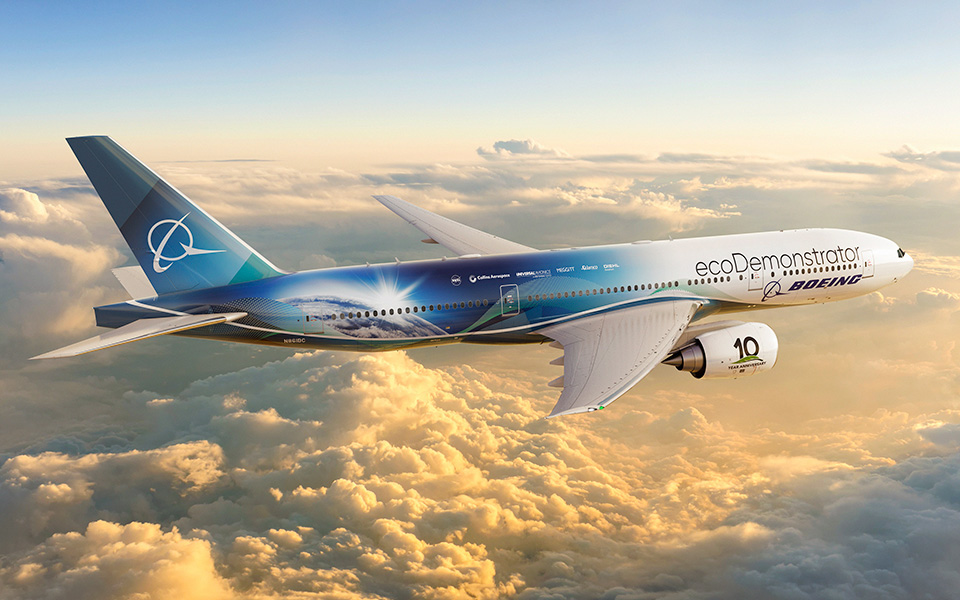

For the past decade, Boeing’s ecoDemonstrator program has accelerated innovation by taking promising technologies out of the lab and testing them in an operational environment to solve real-world challenges for airlines, passengers and the environment. Eleven airplanes have served as flying test beds for the program since it began in 2012.

The latest ecoDemonstrator is a Boeing-owned 777-200ER that will test 19 projects that can make aviation safer and more sustainable.

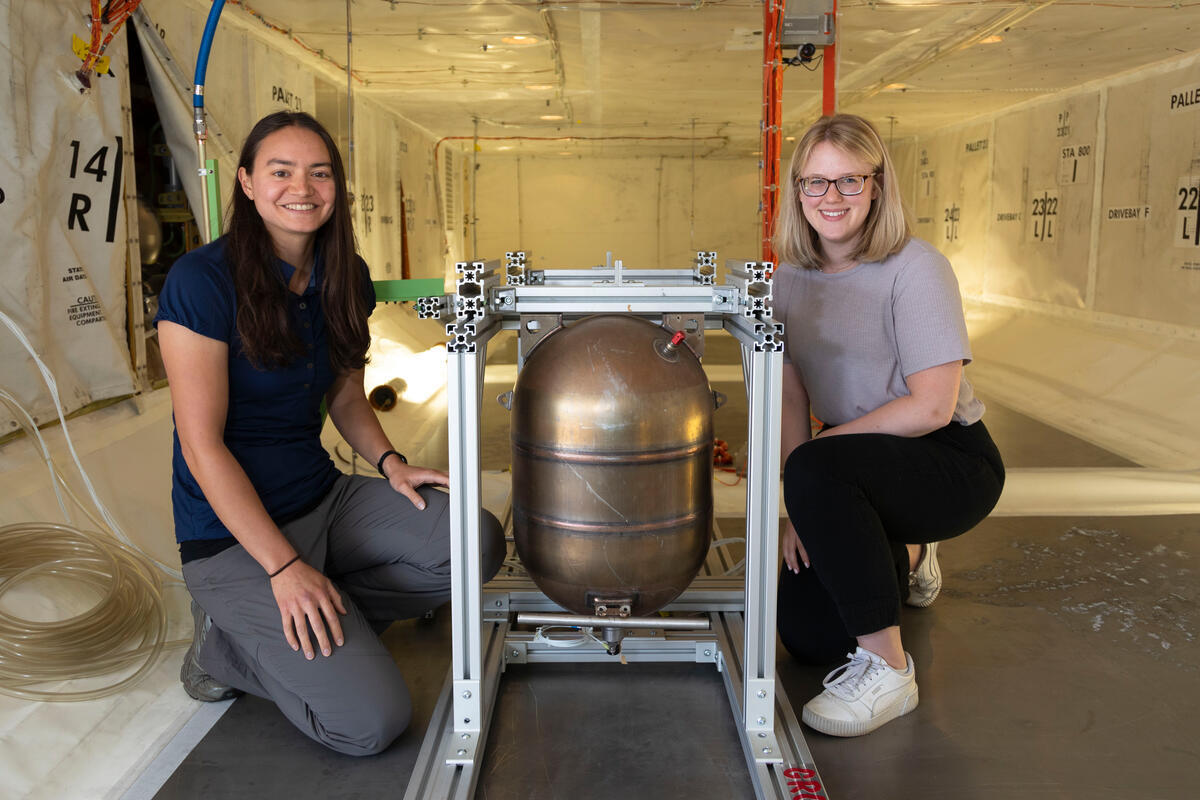

Projects include technologies that improve sustainability and safety for the aerospace industry, including sustainable wall panels in the cargo hold that are made of 40% recycled carbon fiber and 60% resin made from a bio-based feedstock and a fiber optic fuel quantity sensor compatible with 100% SAF.

In 2023, the ecoDemonstrator program also added “Explorer” airplanes that will test specific technologies.